|

|

|||||

Accueil > Actualités > L'Actu des membres et partenaires > Numecas International |

|

|

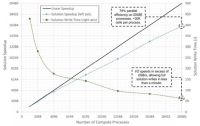

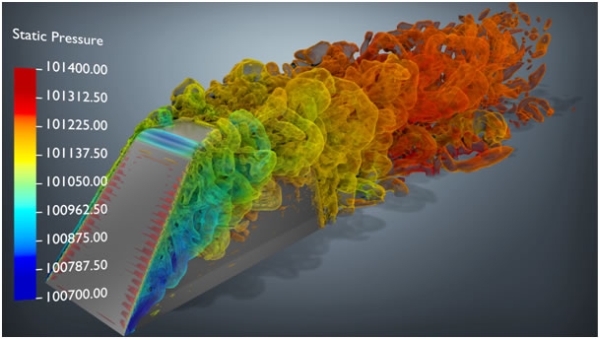

6 septembre 2017 - Recent developments in NUMECA FINE™/Open have yielded impressive improvements in massively parallel performance. More than just improving the scalability of the solver iteration loop, these developments have affected all phases of a typical simulation: solver startup, iteration, and the solution writing. Taken together, these developments allow efficient performance with over 20,000 processes and have made rapid turnaround of high resolution time accurate simulations a reality. In recent years there has been a shift in industrial turbomachinery design and analysis to higher fidelity, higher cost, time-accurate simulations in place of traditional steady state analysis. These simulations allow a deeper understanding of blade passing interaction and other time-varying phenomena which can negatively impact design efficiency. However, this type of simulation presents many significant software challenges:

Recent developments in the NUMECA FINE™/Open solver have addressed both of these problems. First, optimizations to the MPI-based parallel model have yielded efficient parallel performance with over 20,000 processes and a per-process load of less than 30K cells. Second, a comprehensive parallel I/O solution has been implemented with the CGNS-3 file format, allowing scalable initialization, check-pointing, and shutdown of the FINE™/Open solver at any scale. Taken together, these developments have allowed massive unsteady simulations which would have been otherwise unfathomable. In collaboration with Dresser-Rand, high resolution turbomachinery DES simulations have been performed on the OLCF Titan supercomputer using mesh configurations with between 8e7 and 6e8 cells, the largest of which were solved on over 20,000 compute processes. Using the CPUBooster™ module for rapid convergence, and taking advantage of the efficient parallel performance of the FINE™/Open solver, it is now possible to complete each time step in less than 4 minutes including the solution write. This allows a complete solution turnaround time on the order of a few days. |

|

Obtaining even the smallest increase in efficiency in turbomachinery design most often requires significant effort, but can result in largely diminished costs! Think about reduction of material, lower fuel consumption, increased performance, etc. This typically implies evaluating the design not only from a component point of view, but also from a system level, bringing with it various uncertainties (geometrical related to manufacturing - input and boundary conditions, etc). NUMECA’s multiphysics CFD simulation and optimization environment for turbomachinery, combined with Concepts NREC preliminary design tools, is now offered as a unique state-of-the-art integrated & comprehensive end-to-end solution for any turbomachinery design applications: FINE/Agile™. During this seminar we will show you how this software solution can help you achieve those gains in efficiency in your design process as well. Get the chance to learn first-hand about the latest advancements in CFD for turbomachinery. We will explain you the full capabilities of FINE/Agile™ and how it can improve your designs. Industry leaders, like Sebastien Le Martelot from the Centre National d'Études Spatiales (CNES) will be there to talk to you about their best practices and experiences with our software and Eric Zoppellari from AirREDIC who will share expertise about testing and prototyping of rotating machinery. Specific topics:

Products that will be covered during this workshop: FINE/Agile™, AutoGrid5™, HEXPRESS/Hybrid™, FINE™/Turbo, Axial™, Compal® and AxCent® When: Wednesday October 11th 2017, 9:30 am to 5:00 pm |

| 19 janvier 2017 - NUMECA as partner within AllScale will boost runtime efficiency AllScale is an innovative programming approach for ExaScale, decoupling program specification parallelism from management tasks during runtime. Their parallel programming model is based on the nested recursive parallelism, focusing on the following developments:

The above mentioned developments will provide an application independent, reusable codes, taking advantage of combining sophisticated, modular and customizable compiler and runtime system based solutions. As strategic partner within the Allscale project, NUMECA will develop and extend the usage of it's FINE/Open toolchain to exascale HPC. The request from the industry towards higher fidelity CFD and increased simulation reliability is more and more pressing. The use of unsteady LES (Large Eddy Simulation) or DNS (Direct Numerical Simulation) provides an appropriate approach to fulfil such imposed industry demand. However, when applied to industrial cases on complex geometries, such LES/DNS simulations imply very large meshes, ranging from 1 to 10 billion mesh points, yielding problems of 50-100 billions+ degrees of freedom as well as thousands of unsteady time steps. To fulfil those requirements, the cost, in terms of CPU time, needs to be significantly reduced, and the best way to do it, is to increase the number of processors, towards ExaScale HPC (High Performance Computing).

AllScale will boost development productivity, portability and runtime efficiency. It will reduce energy needs, thus improving the resource efficiency utilisation of small to extreme scale parallel systems. The achieved outcomes are validated with applications from fluid dynamics, environmental hazard and space weather simulations; provided from industrial and academic consortium partners. AllScale Objectives

|

|

|

|

|

10 mai 2016 Entreprises dominantes en logiciels de design et analyse de turbomachines, Concepts NREC et NUMECA International ont annoncé un partenariat stratégique pour offrir ensemble leurs capabilités à l’industrie turbomachine. Concepts NREC est bien connu pour son logiciel Agile Engineering Design System®, incluant des modules de design préliminaire pour tout type de turbomachine. NUMECA International est mondialement renommé comme leader des logiciels de mécanique des fluides numériques (CFD) dédiés aux turbomachines. En combinant le meilleur de ces deux entreprises, les clients auront accès à la plus à la pointe des suites de logiciels de turbomachines. Cette solution intégrée ira du design préliminaire jusqu’à l’analyse 3D stationnaire et instationnaire. “Nous travaillons depuis plus de 20 ans avec Concepts NREC et respectons leur compétences en design de turbomachines” déclare Dr. Charles Hirsch, PDG de NUMECA International. “Nous somme impatient de créer un partenariat formel grâce auquel nous pourrons offrir à nos clients les capacités de design préliminaire de Concepts NREC ainsi que celles de génération de géométrie de turbomachines rassemblées dans une même offre.” Dr. David Japikse, PDG de Concepts NREC a déclaré : “Nous utilisons les outils CFD de NUMECA International depuis des décennies maintenant, et avons été impressionnés par les avancées réalisées au niveau vitesse, précision et fonctionnalités au fur et à mesure des années. Nous sommes très content de pouvoir combiner les fonctionnalités NUMECA International à notre Agile Engineering Design System de par ce nouveau partenariat." |

|

| A propos de NUMECA International NUMECA International est un acteur majeur en génération de maillage et solveurs CFD multi-physiques pour des simulations de design et d’optimisation multi-physique de produits industriels. Leader dans le secteur des simulations et optimisations d’écoulements, tout particulièrement dans le marché des turbomachines, naval, aéronautique, aérospatial et multi-physique, NUMECA propose une suite étendue de logiciels couvrant une large gamme d’applications pour des écoulements internes et externes. Poussé par la créativité, l’innovation et la qualité, nous sommes fiers d’avoir su transformer notre passion en outils logiciels utilisés par les plus grandes sociétés. A NUMECA, l’innovation est profondément ancrée dans la science, la physique et dans une riche culture de recherche et développement. A propos des logiciels de NUMECA International Basés sur les technologies les plus avancées, les produits NUMECA sont largement reconnus pour leurs capabilités dédiées par type d’applications, leurs solutions optimales, leur précision, leur vitesse et leur globale simplicité d’utilisation. NUMECA propose des technologies et modèles innovants en réponse à des requêtes industrielles spécifiques, utilisés pour des simulations de fluides, acoustiques, thermiques et fluide/structure dans de larges gammes d’applications. La satisfaction client est notre objectif principal, et nous améliorons de façon continue nos logiciels et services afin de transformer votre processus de design en un réel succès pour votre société. Pour en savoir plus, visitez www.numeca.com. |