|

|||||

Accueil > Activités > Projets R&D > MIEL

MIEL

Porteur : Partenaires du projet : Pour télécharger la fiche du projet,

The three phases described hereafter will end with tools allowing concepts verification. The final goal is to provide engineers with an open strategy to mesh a volume structure, using either tetrahedra or hexahedra, or a mixture of both. The quality of the mesh (element shapes, number of elements) must be the only criterion; so that engineers can concentrate on the sole physical side of the simulation. Finally tools will be implemented in SAMCEF in order to be validated.

DISTENE and INRIA will work mainly on theory and generic tools.

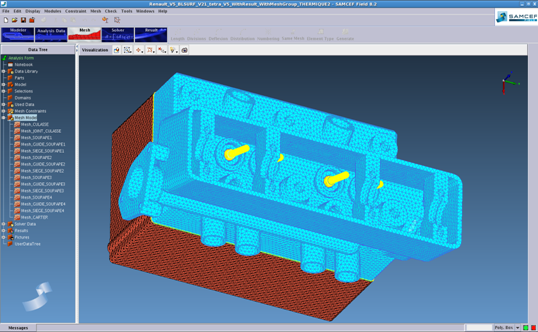

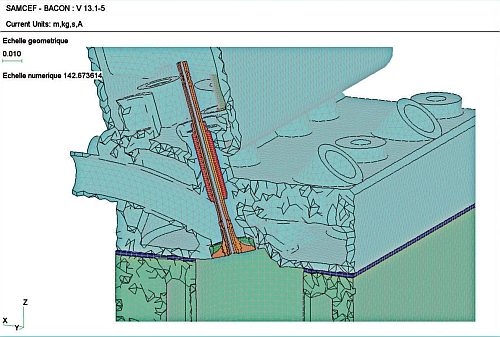

After over 36 months of project progress : INRIA (PhD) continues to work on the automatic mesh for solving Maxwell's equations. The DISTENE algorithms have increasingly robust and fast mesh mixed with a majority of hexahedra (Hexotic tools). SAMTECH France is in the process of finalizing the development of a real industrial tool. Tools developed by DISTENE could be integrated into the infrastructure SAMCEF Field. These tools provide the SAMCEF Field platform essential features to end users in the study. The automatic meshing of complex geometries remains a major concern for the design engineer using finite element codes such as SAMCEF. This task often costly in time will be greatly reduced. The platform allows the automatic mesh generation and thus a considerable saving of time in the creation of meshes created from CAD can be complex. In addition, because of the usability of the tool, several meshes of CAD can be developed in a very short time, making it easier for users in industry.

After starting 18 months ago : INRIA (PhD) works on automatic meshing for Maxwell equation resolution (first version 2D is available). Distene goes on the development of several strategies (tetrahedron, hexahedron thenmixed) in order to improve their algoritms that SAMTECH uses for testing performances and robustness (by plugin in SAMCEF_Field and comparison with other tools) and INRIA is using for non conforming meshes.

|

|